At the center of modern manufacturing, robotic arms are changing the rules of production, mixing quality, safety, and efficiency in ways that were previously unimaginable. The mechanical marvels, often called robot arms – have become indispensable to businesses across the globe, motivated by the need to cut operating costs without sacrificing quality. Robotic arms are being integrated into production lines to reduce cost and increase security. Explore how these innovative machines have transformed the industrial landscape.

Image credit: automatedsolutions.com.au

Cost efficiency is the primary factor behind the widespread adoption of robotic arms. Owners of factories are under constant stress to prevent the risk of injuries at work, eliminate production errors, and cut down on production waste. Robotic arms are able to tackle these challenges. As opposed to humans, robot arms perform repetitive tasks with pinpoint precision that eliminate costly errors and reducing raw material wastage. Robotic arms are employed in industries with high volumes, such as the automotive industry, to guarantee an exact assembly. This precision could translate into significant savings as less defective items mean less work or waste.

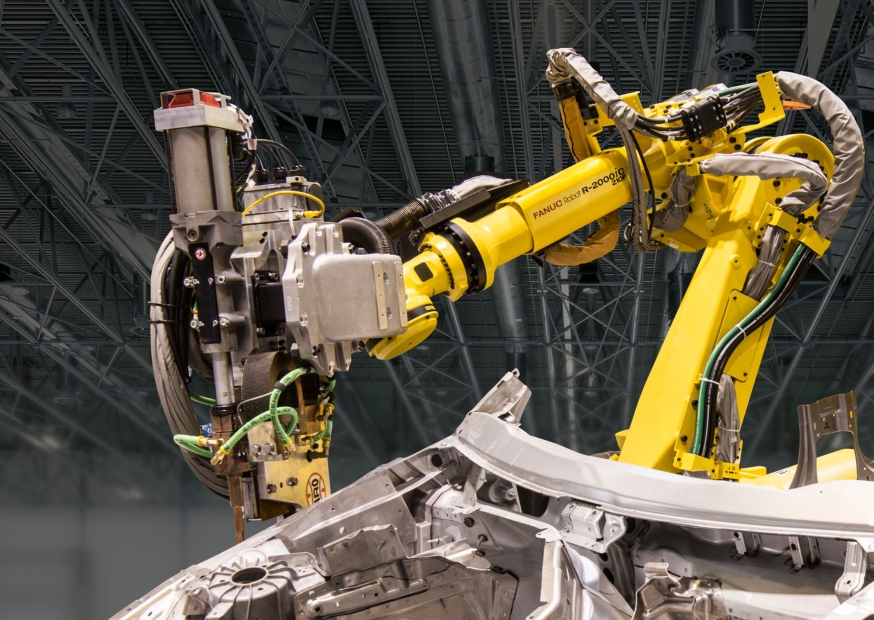

The security of robotic arms is also an important element. There are many manufacturing processes that require handling hazardous materials or operating heavy machinery pose significant risks to workers. By deploying robot arms, companies can remove employees from the dangerous surroundings, dramatically cutting the possibility of workplace injuries. Robotic arms are made up of a number of movable joints which mimic the human arm’s capabilities. However, they operate without any risk of injury. These machines are equipped with robotic hands or end-effectors that can be programmed. They are able to perform tasks like grasping spinning and welding, in conditions that could make it unsafe for humans.

The versatility of robotic arms makes them a game-changer across diverse industries. Robot arms are able to be used for various tasks, ranging from automotive assembly to electronic production. The ability to program these arms allows them to execute complex tasks like painting or applying fiberglass at a remarkable degree of precision. When it comes to warehousing robotic arms have transformed palletizing, automating the process of loading products onto pallets with precision and speed. Automation not only improves efficiency, but also reliability as robot arms are able to work without tiring.

One of the most fascinating advancements in this field is the development of collaborative robots or cobots, which interact with human employees. Cobots with robotic arms, in contrast to traditional industrial robots, which are isolated in cells, are designed to interact with humans safely and seamlessly. In a workplace cobots’ robotic arms may be capable of handling the heavy lifting or tasks that are repetitive, leaving humans to concentrate on more complex responsibilities. The robots can stop or modify their movements whenever they notice a worker in the vicinity.

The effects of robotic arms go beyond safety and effectiveness to the very fabric of manufacturing today. They are crucial to industries that require high precision in tasks such as welding, assembly or material handling. Robot arms, for instance, is able to rotate and position components during assembly in the automotive industry, ensuring that they are perfectly aligned with no human involvement. Robots are also utilized in electronics to care for fragile components. This prevents damage and increases output quality.

As the world’s industries continue to develop robots’ roles will expand. They will be a key element in manufacturing’s future because of their ability to lower costs, enhance safety, and be able to adapt to different tasks. By combining cutting-edge technology with human creativity, robotic arms aren’t just tools. They are partners that drive forward the way we create our world.